Bring professional flight‑sim realism into your cockpit with this full‑scale, heavy‑duty 3D‑printable rudder pedal system. Designed from the ground up for strength, adjustability, and smooth motion, this is my most ambitious 3D‑printed build to date—engineered to withstand real‑world force and deliver a satisfying, authentic feel.

This download includes both STL and CAD files, allowing you to print immediately or customise the design to suit your exact simulator setup.

✅ What This Product Is

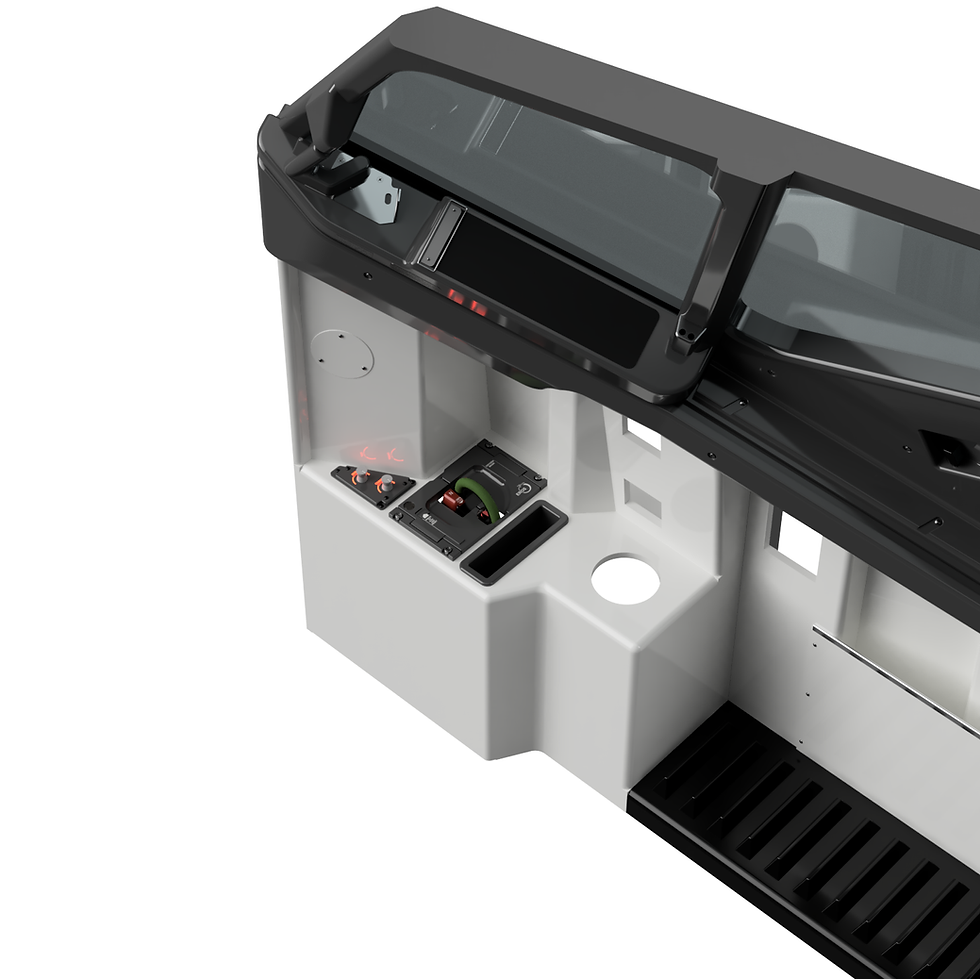

A complete 3D‑printable mechanical design for a real‑size rudder pedal unit featuring:

- 1 x Rudder axis

- 2 x Toe‑brake axes

- Fully supported pedal arms reinforced with metal rods

- Extremely smooth operation using multiple 608 bearings

- 100mm pedal travel adjustment, just like the real aircraft

- A structural design that’s strong, reliable, and visually impressive

This is a DIY digital download consisting of STL + CAD files.

No physical parts, electronics, or hardware are included.

🎛️ Features & Functionality

Realistic Mechanical Design

The system uses a rugged buggy‑track style carriage gliding on six 608 bearings along a sturdy M12 threaded rod. This ensures:

- Smooth, consistent pedal travel

- Excellent load distribution

- Long-term durability even under high stress

Electronics-Ready

Compatible with:

- Arduino Pro Micro (if you prefer your own custom code)

- Leo Bodnar boards for easy plug‑and‑play input mapping

Adjustable & Customisable

You can tailor the unit to your ergonomics or cockpit space:

- Pedals slide forward/backward ~100mm

- CAD files included for custom edits

- Option to replace large cosmetic panels with wood for faster builds

🖨️ Printing Requirements

This is a massive full‑size print, ideal for advanced builders.

- Minimum print bed: 300 × 300 mm

- Print time: ~2 weeks

- Material usage: ~4 rolls of PLA

- Nozzle: 0.4mm used in development, but a 0.8mm nozzle is strongly recommended for large exterior components

Recommended Print Settings

- Cosmetic parts: 2 walls, 15% infill

- Structural parts (arms, supports, load points):

- 6+ walls

- 100% infill

- Modern printers will produce significantly better tolerances; CAD files allow fine adjustments.

🛠️ Engineering Notes

This design is intentionally over‑engineered to withstand the high forces users naturally apply during flight, especially in moments of panic. Most stress‑bearing elements include:

- Metal threaded rods

- Large bearings

- Layer‑orientation‑optimised geometry

This project took me over 6 months at 12 hours a day to design—it’s not at my newest design standard, but it remains one of the most successful builds people have completed over the years and still looks visually stunning.

🎨 Unique Styling

The pedals feature a custom Boeing-inspired logo plate, drawing inspiration from the Bell 212 Huey pedal aesthetic. It’s not found on real Boeing pedals—but adds a tasteful aviation touch.

⚠️ Limitations

- Several essential parts cannot be printed on small printers like the Ender 3/Ender Pro (230×230 mm).

- These large components include:

- Base truck

- Pedal faces

- Vertical pedal connectors with bearing housings

Tip: Advanced users may split models into smaller sections if using compact printers.

FAQ

Q: Can I print this on a 230×230mm printer if I make some parts from wood?

A: Not fully. While some hardware components fit, critical load‑bearing parts exceed 230×230mm. You’ll need at least a 300×300 mm bed or you’ll have to manually split the larger models before printing.